Leading-edge technology is being developed in Prince George which could save the oriented strand board (OSB) industry millions of dollars per year.

UNBC researcher Matt Reid is working with Del-Tech Manufacturing to test the feasibility of using terahertz radiation to improve quality control and reduce raw material input in OSB production. The Northern Development Initiative Trust provided UNBC $200,000 to purchase critical equipment to test the groundbreaking concept.

“This is the fastest terahertz imaging system in Canada right now. With the upgrade, it’ll be one of the fastest terahertz imaging systems in the world,” Reid said. “It’s really only the last few years we’ve looked at terahertz applications. NASA uses it to examine foam on the space shuttle… that’s really the only place that it’s been used so far.”

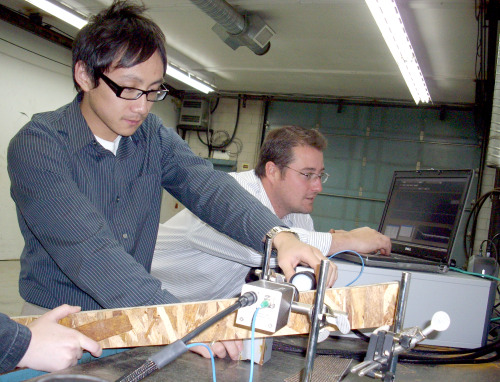

Dian Wang and Dr. Matt Reid test UNBC’s innovative terahertz technology

for scanning and grading Oriented Strand Board (OSB)

Terahertz radiation falls on the light spectrum between microwaves and infrared light, Reid explained. Terahertz radiation passes through many materials like x-rays, without the harmful impact on human health. By passing a terahertz beam through a wooden object and measuring the signal on the other side, Reid is able to “see” inside the wood. “The shape and amplitude of the wave has all the information you need,” he said. “You can see density and fiber structure.”

It is the fiber structure which is most critical to OSB producers. OSB is made by laminating layers of wood chips together, he explained. In order to achieve maximum strength, the fibers of each layer have to lie perpendicular to each other.

Currently, OSB manufacturers have no way to tell how well aligned the fibers are when the boards are made, Del-Tech strategic planner Dennis Callaghan said. They have to produce the boards, and then test them for strength to see if they can be sold. “The mills have to put more flake into the OSB to ensure they meet the standard,” Callaghan said. “With this technology, they could make a 2.5 per cent reduction in raw materials – that’s $2 million a year for an average-size OSB mill.”

In addition, OSB manufacturers would be able to more accurately gauge how strong the boards will be before it’s made, he said. Callaghan toured several OSB plants and found manufacturers were wasting between one and five per cent of their production because it failed to meet specifications. OSB manufacturers represent a major market for the technology, Callaghan added. “OSB has just about replaced plywood in building construction. Eighty per cent of structural panels used today are OSB.”

With the current downturn in the forestry sector caused by the slumping U.S. housing markets, OSB manufacturers have been looking for ways to cut costs. “There is commercial interest in this technology.”

Reid’s interest in Terahertz technology began over five years ago when he was completing his Ph.D. in physics at the University of Alberta. His supervising professor asked him to conduct some experiments attempting to use terahertz radiation for spectroscopy – studying matter through its interaction with light energy. “I told him it wouldn’t work, and he told me to do it anyway,” Reid said. “I tried it on everything on the shelf, and it didn’t work. So I tried it on the (wooden) shelf.”

For the last five years, Reid has been working on developing terahertz technology for a commercial application in the forestry sector. “We were finally able to get the funding to move this forward from the applied research phase to the prototype testing phase,” he said. “This is the critical test of the technology. This will tell if it will work in an industrial setting.” Northern Development Chair Bruce Sutherland says” he is looking forward to BC’s OSB mills having a marketable edge on quality, and creating more jobs”.

Reid hopes to have the feasibility study complete by Oct. 31 and have a working prototype ready by April 2009. The total cost of the year-long project is pegged at over $750,000.

– 30 –

About Northern Development

Northern Development Initiative Trust is an independent regional economic development corporation focused on stimulating economic growth and job creation in central and northern British Columbia. Over $42 million in funding has been committed to 255 projects with a total project value of over $252 million.

Media Contact

Janine North

Chief Executive Officer

Northern Development

Tel: 250?561?2525

info@northerndevelopment.bc.ca